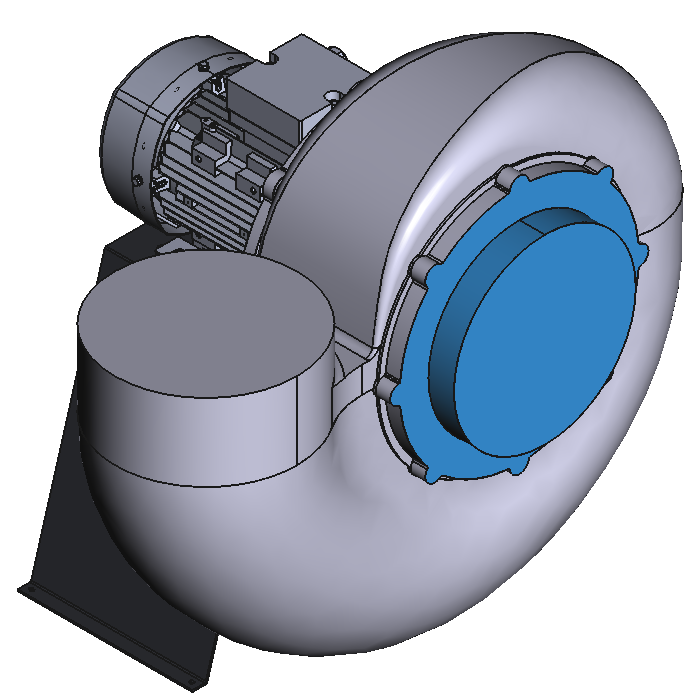

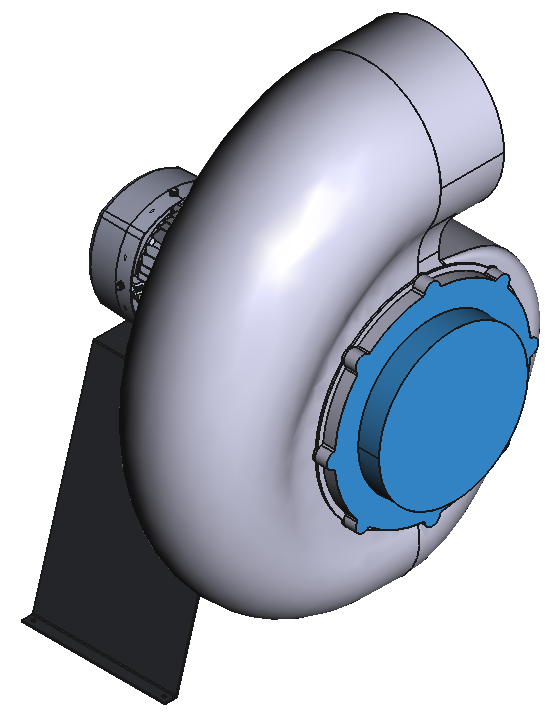

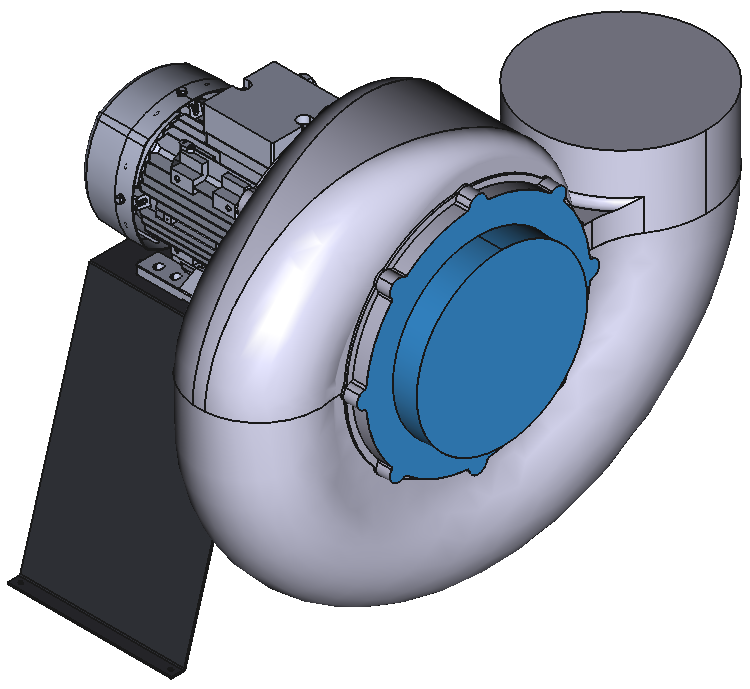

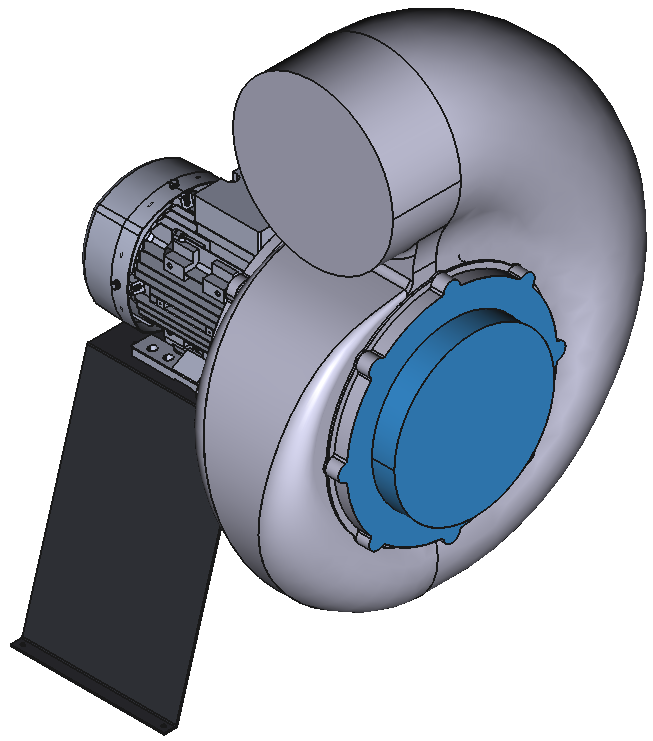

SEAT 30

SEAT 30 - Single phase / LG Position 0°: Left Rotation (engine side view: counterclockwise) / 1.10kw 1450rpm is backordered and will ship once restocked.

Centrifugal fan made of anti-corrosion polypropylene

The SEAT 30 from SEAT Ventilation is a polypropylene centrifugal fan used in laboratories and most industrial extractions.

Its polypropylene volute is suitable for the extraction of corrosive gases with a maximum air flow of 4500m3 /h and a diameter of 250mm in suction and discharge.

In direct drive, the turbine is attached directly to the motor shaft. It can be supplied with single-phase or three-phase motors with a frequency converter to meet the requirements of your installations.

The SEAT 30 is ideal for application in water treatment plants, reclamation plants, wastewater treatment, flue gas/water scrubbing systems, aeration applications, sludge treatment and by-product drying, stripping, sewer and water tunnels, wastewater pumping stations and most industrial extractions.

Hindered amine light stabilizer (HALS) polymer for increased UV resistance.

Easy to install, compact, it has good flow/pressure ratios.

Available in ATEX Zone 2 version

TECHNICAL CHARACTERISTICS

- Air flow: 700-4500m3/h

- Total pressure: 80-800Pa

- Aspiration: diameter 250mm

- Material : polypropylene

- Training : direct

- Option : mounting on metal chair, high protection or roof kit

- Engine : single-phase or three-phase (available in EC)

- Frequency : 50Hz or 60Hz with frequency converter

► Find the right product for your project even more easily, thanks to our online selection software: