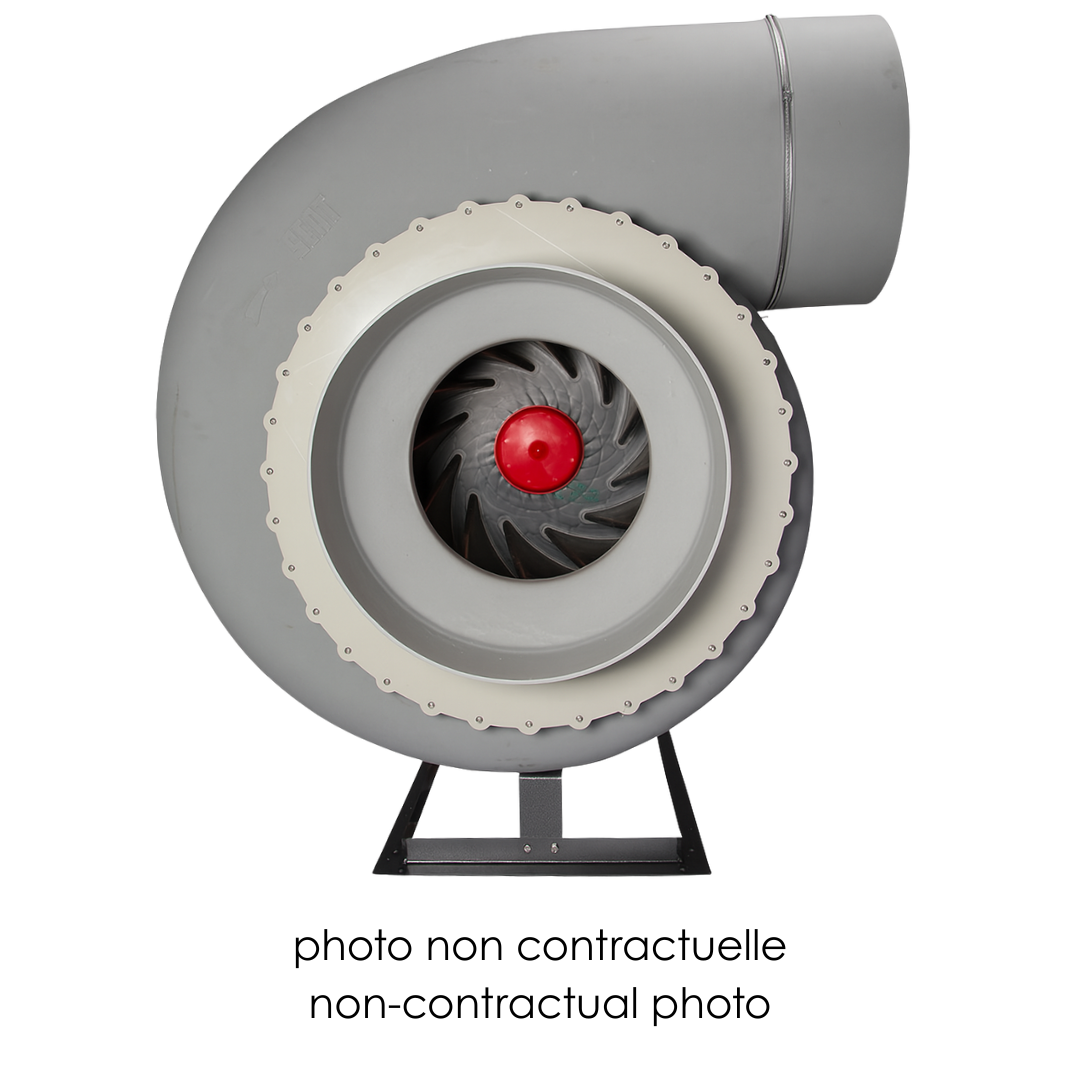

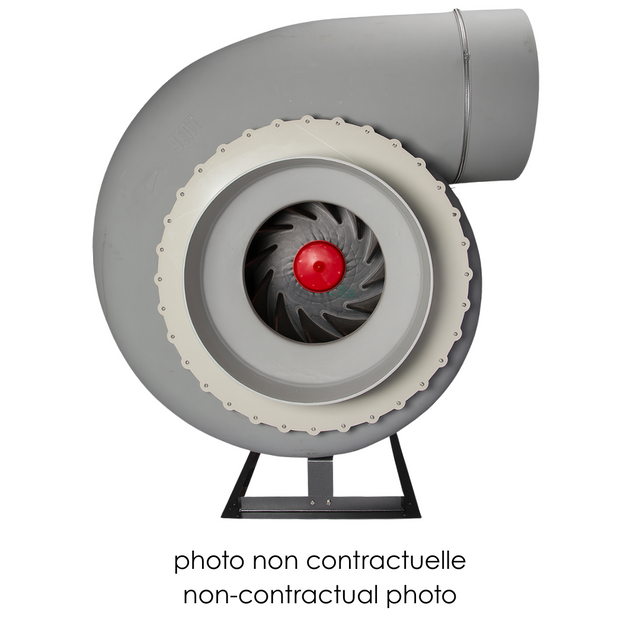

SEAT 50

Price: Contact us

SEAT 50 is backordered and will ship once restocked.

Centrifugal fan made of anti-corrosion polypropylene

The SEAT 50 from SEAT Ventilation is a polypropylene centrifugal fan used for the extraction of corrosive gases with a maximum flow rate of 15000 m³ /h and a diameter of 600mm in suction and 500mm in discharge.

The polypropylene turbine is injection molded using a patented process, the blades are reaction and the turbine is large diameter .

Can be supplied with three-phase motors with mandatory inverter start.

Available in ATEX Zone 2 version

TECHNICAL CHARACTERISTICS

- Air flow: 5000-15000 m³/h

- Total pressure: 300-1800Pa

- Turbine: diameter 775mm

- Suction : 600mm

- Material: polypropylene

- Discharge: 500mm

- Training: direct

- Motor: three-phase

Important: Recommended start with variator.

► Find the right product for your project even more easily, thanks to our online selection software: